What is an airtightness test?

An airtightness test, also often called a blower-through test or pressurization test, is performed to measure the airtightness of an existing home or new building. During the test, a measurement in underpressure and a measurement in overpressure is performed. During each measurement, at different pressures (up to 70 Pa), the leakage rate (air loss) is measured.

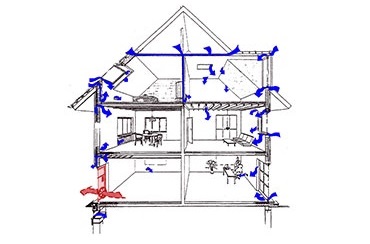

The house is pressurized by installing a frame with sail in an (outside) door or window with in it a calibrated fan. In this way the natural pressure differences caused by wind load on a building can be simulated and it is possible to record this by means of a manometer (air pressure meter).

The measurement is processed in a report and added to an independent quality framework has requested a certificate of conformity that confirms the authenticity of the measurement. In this way you are sure that the measured values are true and you can take maximum advantage of the possible benefits that are associated with it.

Why build airtight?

Research shows that poor airtightness can lead to undesirable phenomena in a home or building. The uncontrolled ventilation through air leaks sometimes means that up to 15% of the heat generated is lost (i.e. a considerably higher energy bill). In some situations, thermal bridges are created that can give rise to local condensation formation. This condensation is the biggest cause of harmful mold formation. In addition, acoustic transmission of outside noises is also linked to poor airtightness of the building structures.

The advantages of airtight construction can be summarized as follows:

» Higher insulation efficiency

» Energy-efficiency points gains

» Energy bill savings

» Correct functioning of ventilation system

» Increased comfort in the home

» Better acoustic performance

» Avoid building damage due to condensation

Detecting air leaks

Under and over pressure are built up during the airtightness test. With this pressure difference, air leaks become tangible and visible with an infrared camera and smoke detection. Thanks to a thermographic analysis the entry of air can be recorded on screen.

To obtain a good airtightness value, it is recommended to prescribe an intermediate or indicative measurement. Advice and possible improvement work are still possible at that time.

Performing an air-tightness measurement

Airtight construction and its control is more of a standard than an exception. Specifications increasingly refer to a requirement in terms of airtightness. With 2020 in sight, these requirements will only increase. Efficient and economically responsible airtight construction is a collaboration between client, architect, contractor and EPB reporter.

» Conducted by a certified airtightness inspector

» BlowerDoortest according to STS-P 71-3 and NBN EN 13829 standard (A-meting)

» Followed by a mandatory external quality framework

» Optional execution of an interim airtightness measurement (B-measurement)

» Measurements of both single-family homes and larger volumes

Single-family homes and large volumes

An airtightness test can be carried out on private homes as well as industrial buildings or office buildings. The airtightness of larger volumes is measured by switching on several fans, the so-called 'MultipleFan' measurement.

A preliminary study, sound advice and the right product choice save costs. In addition, detailed measurements, site follow-up and interim air-tightness measurements ensure a good result regarding the air-tightness of the building envelope.